Precision CNC Manufacturing

Hargo Engineering is an AS9100 certified precision CNC manufacturing company that manufactures complex components to extremely tight tolerances.

Hargo Engineering is an AS9100 certified precision CNC manufacturing company that manufactures complex components to extremely tight tolerances.

Trusted by customers operating in the most demanding of environments around the world.

Our Mission

Contact Hargo Engineering and let us help you elevate your business through our AS9100 certified engineering capabilities.

Our experience tells us many customers struggle to find CNC manufacturers who consistently meet the rigorous standards demanded by industries including aerospace, defence and automotive.

These industries, and many others, demand precision components manufactured to the tightest of tolerances. That’s why demanding customers choose Hargo Engineering as their trusted manufacturing partner.

Contact

Our AS9100 certification ensures every component we produce is manufactured to the highest possible industry standards.

Our strict quality management system guarantees each component meets the strictest quality standards, ensuring your peace of mind.

Our commitment is to stay on schedule, ensuring you receive your components exactly when you need them.

100’s of customers, over nearly 50 years, count on Hargo Engineering as their trusted partner - delivering consistent solutions for all their CNC manufacturing needs.

Our Services

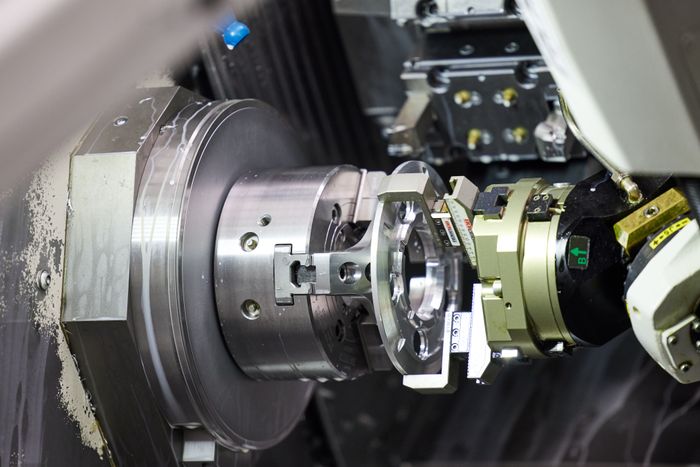

Turning, Milling & Grinding

Including drawing design revision & fault ID

Subcontractor management, warehousing, assembly and logistics management

Equipped with the latest turning and milling machines, our bespoke, state of the art facility manufactures complex components up to 225mm in diameter (and 450mm x 450mm on our mills) designed to withstand extreme environments, incl. shock, vibration, temperature cycling, and foreign substances for a variety of applications.

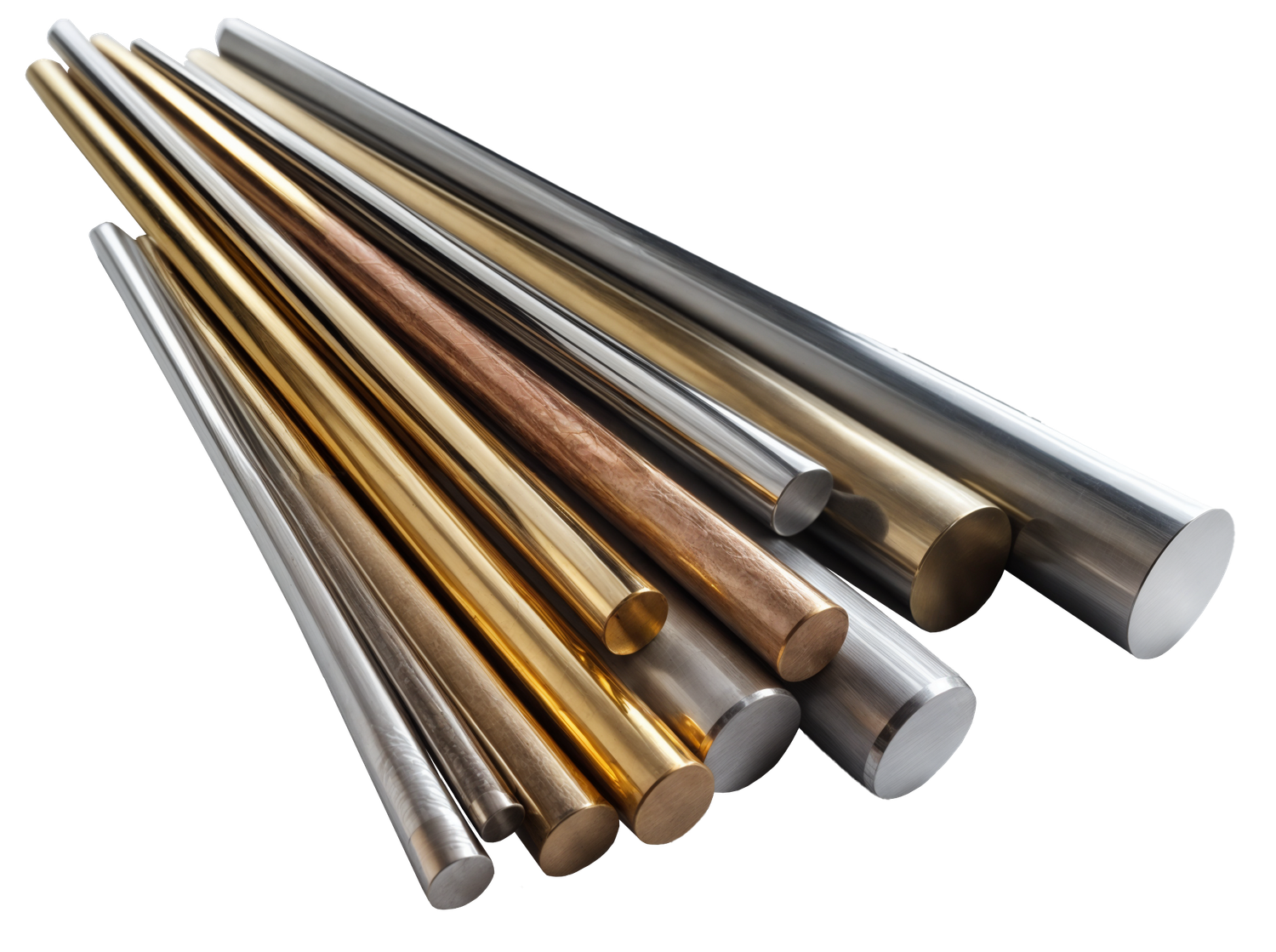

Our flexible machining capabilities ensure we are experienced machining a diverse range of alloys and composite raw materials to MIL-SPEC + aerospace specifications, offering multiple solutions to meet your unique requirements.

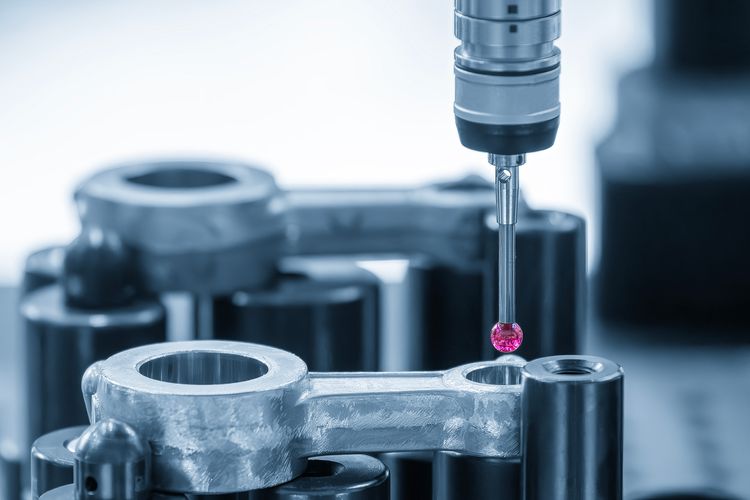

Right first time

Quality is at the forefront of everything we do. Our AS9100 certified Quality Management System ensures every component we produce meets the highest possible quality standards to meet your unique specifications.

years of experience

yield over 10+ years

years export experience

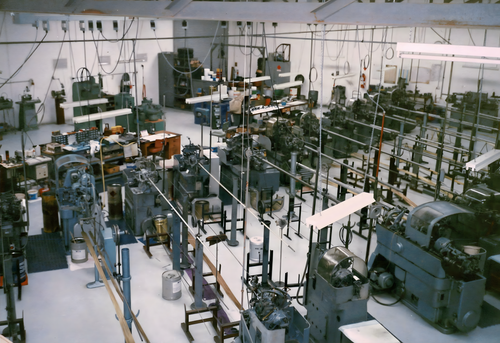

A need for high precision engineering in the Australian marketplace.

In 1976, Heinz Gogol, who had already amassed 16 years of experience in the German precision engineering industry, saw a need for high precision engineering of complex, small components in the Australian marketplace. Heinz’s vision lead to the creation of Hargo Engineering.

Being accustomed to the rigours of the precision manufacturing industry, Heinz soon developed a reputation for innovation and supplying high quality components to an ever growing customer base.

This reputation and passion for precision CNC manufacturing continues with his son Frank, and Hargo’s team of experienced tradespeople, who has followed in his father’s footsteps with a pride that is synonymous with his German heritage.

We are focussed on building long term partnerships with our customers. We actively invest in new technology to assist our customers with increased efficiency, accuracy, and value.

Our team is passionate about turning our customers’ ideas and concepts into reliable solutions for applications across the globe. Known for our commitment to customer service, we listen to our customers to ensure we deliver on our promise to you – high quality components delivered on time.

Adrian Campbell

Business Development Manager

Ph +61 (0) 3 9761 5110

M +61 (0) 418 171 072

Adrian.c@hargo.com.au

103-115 Merrindale Dr, Croydon South VIC 3136, Australia

Monday - Friday: 7 AM - 5 PM